How many types of circuit board PCBs can be divided by material? Where are they all used?

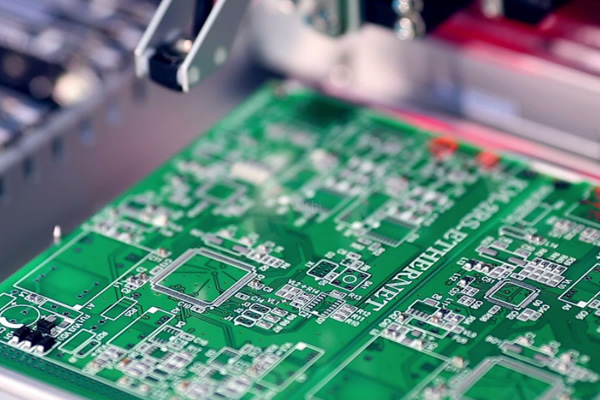

The substrate materials used for general PCB boards can be divided into two categories: rigid substrate materials and flexible substrate materials. The most common rigid substrate material is copper-clad board.

Copper-clad board is a product made by using wood pulp paper or fiberglass cloth as reinforcing materials, impregnated with resin, and covered with copper foil on one or both sides, and hot pressed. When used in the production of PCB multilayer boards, it is also called core board (CORE).

At present, the supply of copper-clad laminates in the market can be mainly divided into the following categories based on the substrate: paper substrate, fiberglass cloth substrate, synthetic fiber cloth substrate, non-woven fabric substrate, and composite substrate.

Currently commonly used PCB substrate materials

1. G-10 and G-11 laminates

They are epoxy fiberglass laminates that do not contain flame retardants and can be drilled using a drilling machine, but punching with a punch is not allowed. The performance of G-10 is extremely similar to that of FR-4 laminates, while G-11 can withstand higher operating temperatures.

2. FR-2, FR-3, FR-4, FR-5, and FR-6 laminates (all of which contain flame retardants and are therefore named "FR")

FR-2 laminated board: Its performance is similar to XXXPC, and it is a paper-based phenolic resin laminated board that can only be punched with a punching machine, not drilled with a drilling machine.

FR-3 laminate: It is a paper-based epoxy resin laminate that can be punched at room temperature.

FR-4 laminates: It is an epoxy glass fiber laminate with extremely similar properties to G-1 laminates, with good electrical and processing properties, and a desirable cost performance ratio. It can be used to make multi-layer boards. It is widely used in industrial products.

FR-5 laminate: It has similar performance to FR-4, but can maintain good strength and electrical performance at higher temperatures.

FR-6 laminate: It is a polyester resin fiberglass laminate.

Among the above-mentioned layers, the commonly used G-10 and FR-4 are suitable for multi-layer printed circuit boards, which are relatively inexpensive and can use drilling machine drilling technology, making it easy to achieve automated production.

3. Non epoxy resin laminates. There are several commonly used non epoxy resin laminates:

Polyimide resin glass fiber laminates

It can be used as a rigid or flexible circuit substrate material, and its strength and stability are better than FR-4 laminates at high temperatures. It is commonly used in highly reliable military products.

GX and GT laminates

They are polytetrafluoroethylene glass fiber laminates, and the dielectric properties of these materials are controllable and can be used in products with strict dielectric constant requirements. GX has better dielectric properties than GT and can be used in high-frequency circuits.

XXXp and XXXPC laminates

They are phenolic resin paper base boards that can only be punched and not drilled. These layer boards are only used for single-sided and double-sided printed circuit boards and cannot be used as raw materials for multi-layer printed circuit boards. Due to their low price, they are widely used as circuit substrate materials in civil electronic products.